Views: 0 Author: Site Editor Publish Time: 2022-10-17 Origin: Site

The choice of laser welding machine is very important to the yield of batch processing; therefore, users should try their best to choose high-quality laser welding machines under the premise of conditions permitting.

What are the production characteristics of laser welding machine?

What are the production advantages of laser welding machines?

What is the reason for choosing a laser welding machine?

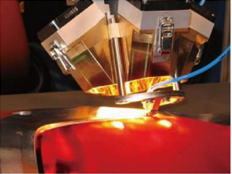

Due to the small spot (0.1~0.3mm) and high power density of the laser beam after focusing, the laser welding machine is several orders of magnitude higher than arc welding (5×102~104W/cm2), so laser welding has the incomparable advantages of traditional welding methods. Significant advantages: small heating range, narrow welding seam and heat-affected zone, excellent joint performance; small residual stress and welding deformation, high-precision welding can be achieved; high melting point, high thermal conductivity, heat-sensitive materials and non-metals can be welded; Fast welding speed and high productivity; highly flexible and easy to automate.

1: The workpiece processed by the laser welding machine can be placed in a closed space (after being evacuated or the internal gas environment is under control).

2: The laser beam can be focused on a small area, so that small and closely spaced small parts can be welded.

3: There are many types of weldable materials, and they can also combine various materials with different materials.

4: It is easy to use automation for high-speed welding, not only that, but also digital or computer control.

5: When welding very thin materials or wires with relatively thin diameters, the laser welding machine will not have the trouble of melting back like arc welding.

6: The laser welding machine is not affected by the magnetic field (arc welding and electron beam welding are easily disturbed by the magnetic field), so that the weldment can be aligned more accurately.

The laser welding machine has the advantages of high speed, large depth and small deformation;

The laser welding machine can weld at room temperature or under special conditions, and the welding equipment is simple. For example, when the laser passes through the electromagnetic field, the beam will not be deflected; the laser can be welded in vacuum, air and a certain gas environment, and can be welded through glass or materials that are transparent to the beam;

The laser welding machine can weld refractory materials such as titanium, quartz, etc., and can weld heterogeneous materials with good results. Before starting the laser welding machine, firstly check the components in the optical path such as YAG rod, dielectric diaphragm and lens protective glass, and make sure that each optical component has no abnormal phenomena such as dust pollution and mildew. Each optical component will not be damaged under strong laser irradiation.

Wuhan EETO Laser Equipment Co., Ltd, which has been established for several years, focuses on the production of laser welding machines. Here, you can find the laser welding machines you need.