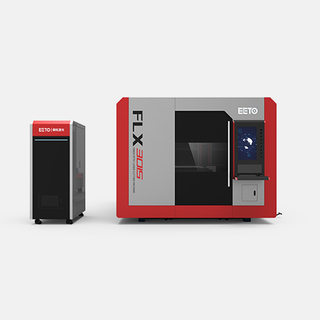

No. 99, Jinxiu Avenue, Wulijie, Jiangxia District Wuhan, China.

Plug & Play

Most Electrical Wiring works are eliminated by Intergrated Connection Design. Just Plug - n - Play.

Connect & Ready to Start

Connect Gas Supply to Prepared Gas Connectors, and All Gas System is Ready.