Language

Author: Site Editor Publish Time: 11-05-2025 Origin: Site

In the shipbuilding industry, precision and efficiency are crucial when processing large and thick steel plates. However, traditional cutting methods such as plasma and oxy-fuel cutting often lead to thermal deformation, low accuracy, and high rework rates.

To meet modern shipbuilding demands, manufacturers are now turning to fiber laser cutting technology, a faster, cleaner, and more precise solution for large-scale metal processing.

Shipbuilding involves large-format and high-thickness metal sheets that must meet strict welding and assembly standards. Traditional cutting systems face several key challenges:

Severe thermal deformation from high-temperature plasma or flame cutting.

Low cutting accuracy, leading to poor fit-up during welding.

Slow cutting speed and heavy reliance on manual rework.

High energy consumption and maintenance costs.

These issues not only reduce production efficiency but also increase labor and material waste, a major concern for modern shipyards aiming to improve productivity and sustainability.

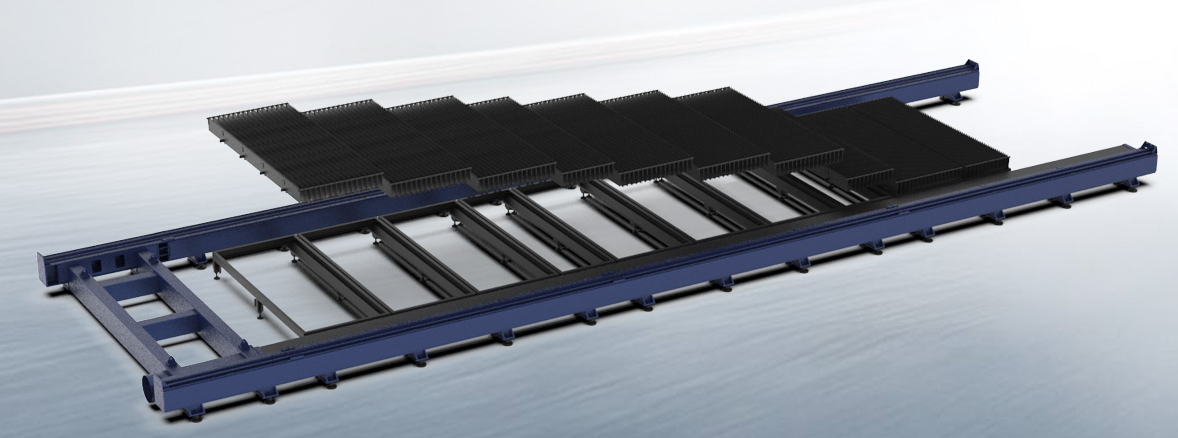

The FGT series is specially designed for cutting large-format thick plates. Compared with traditional plasma cutting machines, laser cutting has higher precision and faster speed. The biggest difference between the FGT series laser cutting machine and the traditional laser cutting machine is whether the cutting table is connected to the machine body. The high-power laser beam still has very strong energy after penetrating the metal material, which will cause irreversible damage to the machine body. The split body design is the best option. Because the high temperature generated during laser cutting will not be transmitted to the machine gantry through the cutting table to avoid deformation. After a long time of cutting, the working table can be replaced by the customers themselves.

Different from the steel rail transmission used by the gantry plasma cutting machine, FGT's gantry cutting machine adopts high-precision rack and pinion transmission, with higher acceleration, cutting accuracy and cutting speed. Powered by high-power fiber laser sources, the FGT easily handles thick shipbuilding plates, maintaining smooth edges and consistent cutting quality.

EETO FGT supports bevel laser cutting up to 55°, enabling one-step cutting and welding preparation. No secondary machining required, reducing time and costs significantly.

Support V/X/Y/K beveling cutting. The design cutting angle is ±55 degrees, and a certain safety distance is reserved for the interference between the device and the plate.

In the traditional integrated structure, the high temperature generated during laser cutting will be transmitted to the bed body, which will cause deformation after long-term cutting, thereby affecting cutting accuracy. The split design solved this and ensured lasting precision and mechanical stability.

Fiber laser technology reduces energy consumption compared with plasma or flame systems. Additionally, EETO allows local production of the working table, helping users and distributors save on shipping and setup costs.

The modular table design can be replaced very easily, simplifying maintenance and minimizing downtime, ideal for 24/7 shipyard operations.

At EETO, we believe that our customers' challenges are our challenges. The FGT series embodies this philosophy through:

Due to the high risk of pollution during optical fiber installation, connecting the fiber to the cutting head at the customer's site is an extremely challenging task. To address this issue, we have adopted a separate routing approach for the optical fiber cable. This eliminates the need for disassembly before delivery and significantly reduces the possibility of fiber contamination.

With the multi-chamber high-efficiency suction system, the suction position can follow the movement of the cutting area, thus the suction can always stay high and good effect.

The gas circuit control system can help filter impurities in the gas, switch between different cutting gases more conveniently, and alarm in time when the gas is exhausted to protect the cutting head.

High Voltage Protection

Europe Standard Electrical Circuit Design

Safety Relay Protection

EtherCAT Control System

Wireless WIFI Connection

EETO FGT Series has been widely adopted by shipyards and heavy steel manufacturers around the world. The future of shipbuilding demands precision, efficiency, and flexibility. And EETO delivers all three with the FGT Ground Rail Gantry Fiber Laser Cutting Machine.

If you're ready to upgrade your production line and achieve faster, cleaner, and more reliable cutting performance, or if you would like to have more metal processing demand. Please contact us today:

Email: sales@eetomachinery.com

WhatsApp No: +8613720134093